STAINLESS STEEL REACTOR

设计标准:GB150-2011《压力容器》 | ASME Section VIII Div.1

Design Standards: ASME Section VIII Div.1 | PED 2014/68/EU

Component | Material Options | Properties |

Main Vessel | 304/316L/321 Stainless Steel | Tensile strength ≥515 MPa, Ra≤0.8μm (electropolished) |

Heat Exchange | Jacket/Half-pipe Coil/Internal Coil | Jacket pressure 0.6MPa, Half-pipe pressure 2.5MPa |

Sealing | Mechanical Seal (double) + PTFE Gasket | EN 12756 leakage standard (≤10 ppm) |

Heating Methods

Electric: 380V/50Hz, power density ≤3.5W/cm²

Steam: Saturated steam ≤0.8MPa

Thermal Oil: Temperature control ±1℃

Agitation System

Paddle/Turbine/Anchor type

Speed 0~300 rpm (VFD control)

Connections

Flanges: HG/T 20592 DN50~DN200

Quick Clamps: ISO 2852

Advantage | Technical Highlights |

High Strength | Operating pressure up to 4.0MPa (hydrotest 6.0MPa) |

Sanitary Grade | Complies with GMP 2023 Class D cleanliness |

Rapid Heating | Jacket heating rate ≥3℃/min (2000L volume) |

Cost Efficiency | 20-year service life, maintenance cost 40% lower than glass-lined reactors |

Parameter | Standard Range | Custom Options |

Volume | 100L~20,000L | Up to 50,000L |

Temperature | -196℃~+350℃ | +450℃ (special design) |

Vacuum | ≤0.095MPa | ≤1×10⁻³ Pa (high vacuum) |

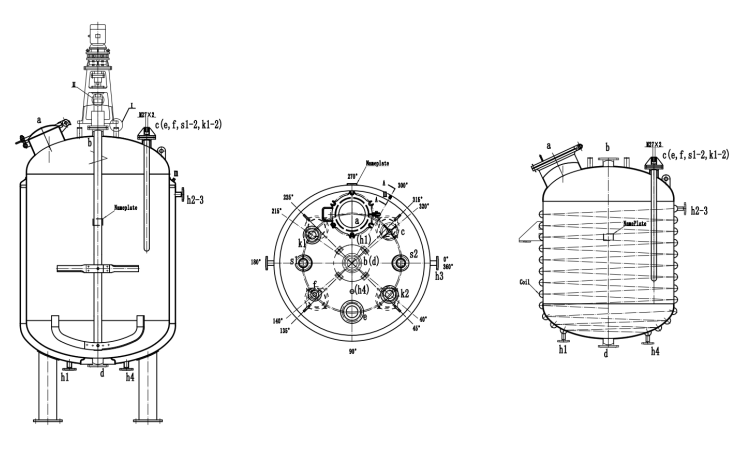

Nozzle 管口 | Connection standard 连接尺寸 | Application用途 |

a | / | Manhole 人孔 |

b | HG/T20592-2009 | Agitator hole 搅拌孔 |

c | HG/T20592-2009 | Temperature hole 温度计口 |

d | HG/T20592-2009 | Discharge hole 排净口 |

e | HG/T20592-2009 | Reserve hole 备用口 |

f | HG/T20592-2009 | Pressure gauge 压力表口 |

S1-2 | / | Sight glass hole 视镜口 |

H1-4 | HG/T20592-2009 | Jacket inlet and outlet hole 夹套进出口 |

K1-2 | HG/T20592-2009 | Reserve hole 备用口 |

m | Inner screw, G1/2” | Jacket vent hole 气体出口 |